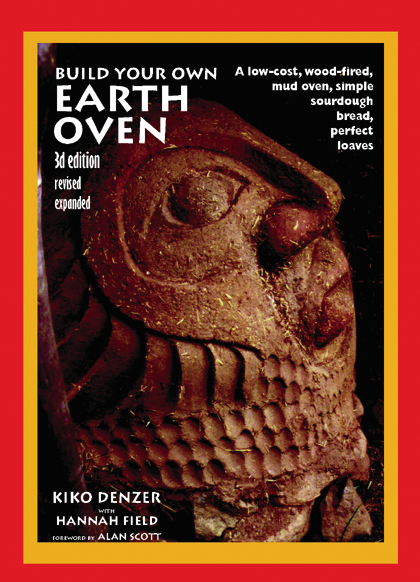

Build Your Own Earth Oven

A Low-Cost Wood-Fired Mud Oven, Simple Sourdough Bread, Perfect Loaves, 3rd Edition

Build Your Own Earth Oven

A Low-Cost Wood-Fired Mud Oven, Simple Sourdough Bread, Perfect Loaves, 3rd Edition

Earth ovens combine the utility of a wood-fired, retained-heat oven with the ease and timeless beauty of earthen construction. Building one will appeal to bakers, builders, and beginners of all kinds, from:

• the serious or aspiring baker who wants the best low-cost

bread oven, to

• gardeners who want a centerpiece for a beautiful

outdoor kitchen, to

• outdoor chefs, to

• creative people interested in low-cost materials and

simple technology, to

• teachers who want a multi-faceted, experiential project for students of all ages (the book has been successful with

everyone from third-graders to adults).

Build Your Own Earth Oven is fully illustrated with step-by-step directions, including how to tend the fire, and how to make perfect sourdough hearth loaves in the artisan tradition. The average do-it-yourselfer with a few tools and a scrap pile can build an oven for free, or close to it. Otherwise, $30 should cover all your materials–less than the price of a fancy “baking stone.” Good building soil is often right in your back yard, under your feet. Build the simplest oven in a day! With a bit more time and imagination, you can make a permanent foundation and a fire-breathing dragon-oven or any other shape you can dream up.

Earth ovens are familiar to many that have seen a southwestern “horno” or a European “bee-hive” oven. The idea, pioneered by Egyptian bakers in the second millennium BCE, is simplicity itself: fill the oven with wood, light a fire, and let it burn down to ashes. The dense, 3- to 12-inch-thick earthen walls hold and store the heat of the fire, the baker sweeps the floor clean, and the hot oven walls radiate steady, intense heat for hours.

Home bakers who can’t afford a fancy, steam-injected bread oven will be delighted to find that a simple earth oven can produce loaves to equal the fanciest “artisan” bakery. It also makes delicious roast meats, cakes, pies, pizzas, and other creations. Pizza cooks to perfection in three minutes or less. Vegetables, herbs, and potatoes drizzled with olive oil roast up in minutes for a simple, elegant, and delicious meal. Efficient cooks will find the residual heat useful for slow-baked dishes, and even for drying surplus produce, or incubating homemade yogurt.

Reviews and Praise

"... the essential book…worth many times its price in avoided labor and frustration"--Dan Wing, author, The Bread Builders: Hearth Loaves & Masonry Ovens

More Reviews and Praise

"[It] will awaken in you...the artisan vision, where earth meets hand meets spirit"--Peter Reinhart, author, Crust and Crumb

"Creative. Innovative. Brilliant. ...the definitive book on how to build an adobe oven..."--William Rubel, author, The Magic of Fire

"...simplicity itself: brief, brisk, artful, and well-written....empowering throughout...fruit of a new movement for sustainability, it celebrates the pleasure of living well with the earth."--Peter Bane, Permaculture Activist

Reviews and Praise

"... the essential book…worth many times its price in avoided labor and frustration"--Dan Wing, author, The Bread Builders: Hearth Loaves & Masonry Ovens

"[It] will awaken in you...the artisan vision, where earth meets hand meets spirit"--Peter Reinhart, author, Crust and Crumb

"Creative. Innovative. Brilliant. ...the definitive book on how to build an adobe oven..."--William Rubel, author, The Magic of Fire

"...simplicity itself: brief, brisk, artful, and well-written....empowering throughout...fruit of a new movement for sustainability, it celebrates the pleasure of living well with the earth."--Peter Bane, Permaculture Activist