| Pages: | 360 pages |

| Book Art: | Full-color illustrations charts throughout |

| Size: | 8 x 10 inch |

| Publisher: | Chelsea Green Publishing |

| Pub. Date: | October 1, 2005 |

| ISBN: | 9781931498913 |

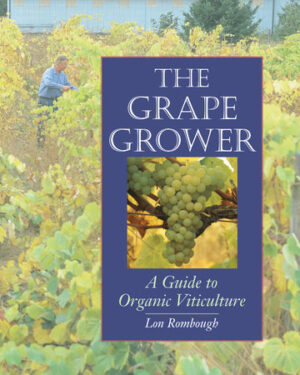

The Apple Grower

Guide for the Organic Orchardist, 2nd Edition

For decades fruit growers have sprayed their trees with toxic chemicals in an attempt to control a range of insect and fungal pests. Yet it is possible to grow apples responsibly, by applying the intuitive knowledge of our great-grandparents with the fruits of modern scientific research and innovation.

Since The Apple Grower first appeared in 1998, orchardist Michael Phillips has continued his research with apples, which have been called “organic’s final frontier.” In this new edition of his widely acclaimed work, Phillips delves even deeper into the mysteries of growing good fruit with minimal inputs. Some of the cutting-edge topics he explores include:

- The use of kaolin clay as an effective strategy against curculio and borers, as well as its limitations

- Creating a diverse, healthy orchard ecosystem through understory management of plants, nutrients, and beneficial microorganisms

- How to make a small apple business viable by focusing on heritage and regional varieties, value-added products, and the “community orchard” model

The author’s personal voice and clear-eyed advice have already made The Apple Grower a classic among small-scale growers and home orchardists. In fact, anyone serious about succeeding with apples needs to have this updated edition on their bookshelf.

Reviews & Praise

"A must read for anyone who grows apples or is contemplating doing so."—Lee A. Reich, garden author and Associated Press syndicated columnist

“Michael Phillips’ revised The Apple Grower has as much help as you’ll find anywhere to get you to that first bite of pie or sip of cider. The previous edition, published in 1998, was the bible for many backyard orchardists and commercial organic growers. The new edition, boasting color photos and expanded and better-organized chapters, is a real treat for anyone interested in apples. The new edition’s chapter on diseases and pests will be helpful to those left scratching their head about who or what is eating the apples or trees they are trying to grow. Phillips’ style is more writerly than reference. His homespun stories about his many years of trying to outwit and outmaneuver the legions of apple-loving creatures are both entertaining and packed with tips. Phillips’ extremely handy compendium of orchard tasks has always served as my basic plan of attack for what to do in my orchard, and the revised and expanded edition will be a welcome addition to my library. I have no doubt that over time it will take on the grimy, thumbed-through, and well-used look of my copy of the first edition of The Apple Grower.”—Northern Woodlands