Designing Leather Goods: Cutting & Shaping

In a personal investigation into ethical and traceable leather, fashion designer Alice Robinson begins a ground-breaking journey into the origin story of leather and its connection to food and farming. Keep reading to learn more about her process of cutting & shaping leather to create handbags, shoes, clothing, and more!

The following is an excerpt from Field, Fork, Fashion by Alice V Robinson. It has been adapted for the web.

Cutting & Shaping Leather

‘Leather has a 3D memory, if you cut the shoulder of a cow, it will return. The power of the leather is stronger than the will of the designer’, words imparted years earlier by a production manager at a luxury Italian manufacturer, a warning that still rang true.

‘We roughly throw away half of the leather we order, because of the way in which we need to cut the specific pieces.’ I thought of this as I looked at the hide. It was evident some sections had more consistency than others and these areas only extended so far.

The Structure of Leather

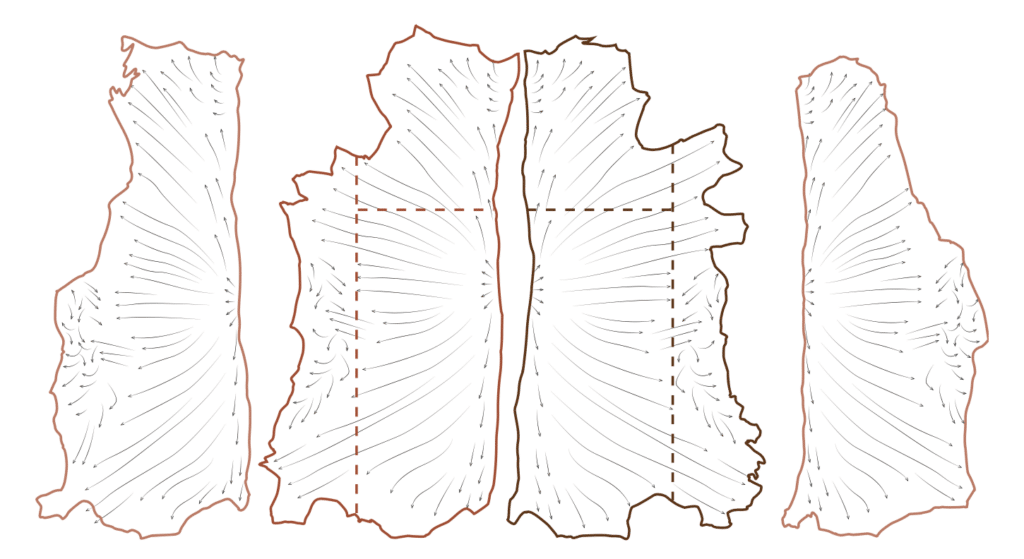

Before I could design, I needed to consider how the structure of the leather changed within each side. Often in leather production these changes in fibre structure are distinguished by dividing the hide into sections, most commonly by the shoulders, backs (bends) and bellies, as each have a distinctively different feel.

I had previously seen these sections cut off before the tanning process began. First to go was the belly.

Shaping: Starting the Tanning Process

A continuous vertical strip cut from the side of the hide.Much like our bellies, it is softer and looser than the rest of the body. This sort of fibre structure makes it more susceptible to wrinkling once in the form of leather and so is less suited to applications where it may need to be stretch resistant.

With the belly removed from either side, the hide begins to look more rectangular.

Next to be separated is the shoulder, a horizontal division across the upper half of the body. Less dense in its fibre composition and sitting at the base of the neck, it is more flexible because of the head movements. Its consistent thickness makes the shoulder easy to work with and a popular part of the hide for bag making.

The piece that remains is called the butt – or if split again down the spine, each piece is called a bend – it has a tightly compact fibre structure making it the strongest and most consistent part of the hide. It is also the largest cut, almost rectangular apart from the bottom end tapering in the centre where the tail once was.

Recommended Reads

The Future of Sustainable Fashion: A “Farm-to-Closet” Vision

Recent Articles

Tips for Seed Saving · You either have dry seeds or wet seeds. Proper drying & storing is essential so they can germinate months (or even years) down the road.

Read MoreWhen you have a family Cow, you have it all. The cow is the most productive, efficient creature on earth. She will give you fresh milk, cream, butter, and cheese, build human health and happiness, and even turn a profit for homesteaders and small farmers who seek to offer her bounty to the local market or neighborhood.

Read MoreBeekeeping has surged in popularity as more people set up backyard hives. Embrace the buzz and transform your backyard into a thriving haven for bees!

Read MoreWhen you save seeds, you become a plant breeder! Take control of your seeds and grow the best traditional and regional varieties and even develop your own.

Read MoreSave seeds, save the future! Embracing the tradition of saving seeds is a powerful practice for both home gardeners and seasoned horticulturists alike. Take control of your garden’s destiny – start saving seeds today!

Read More