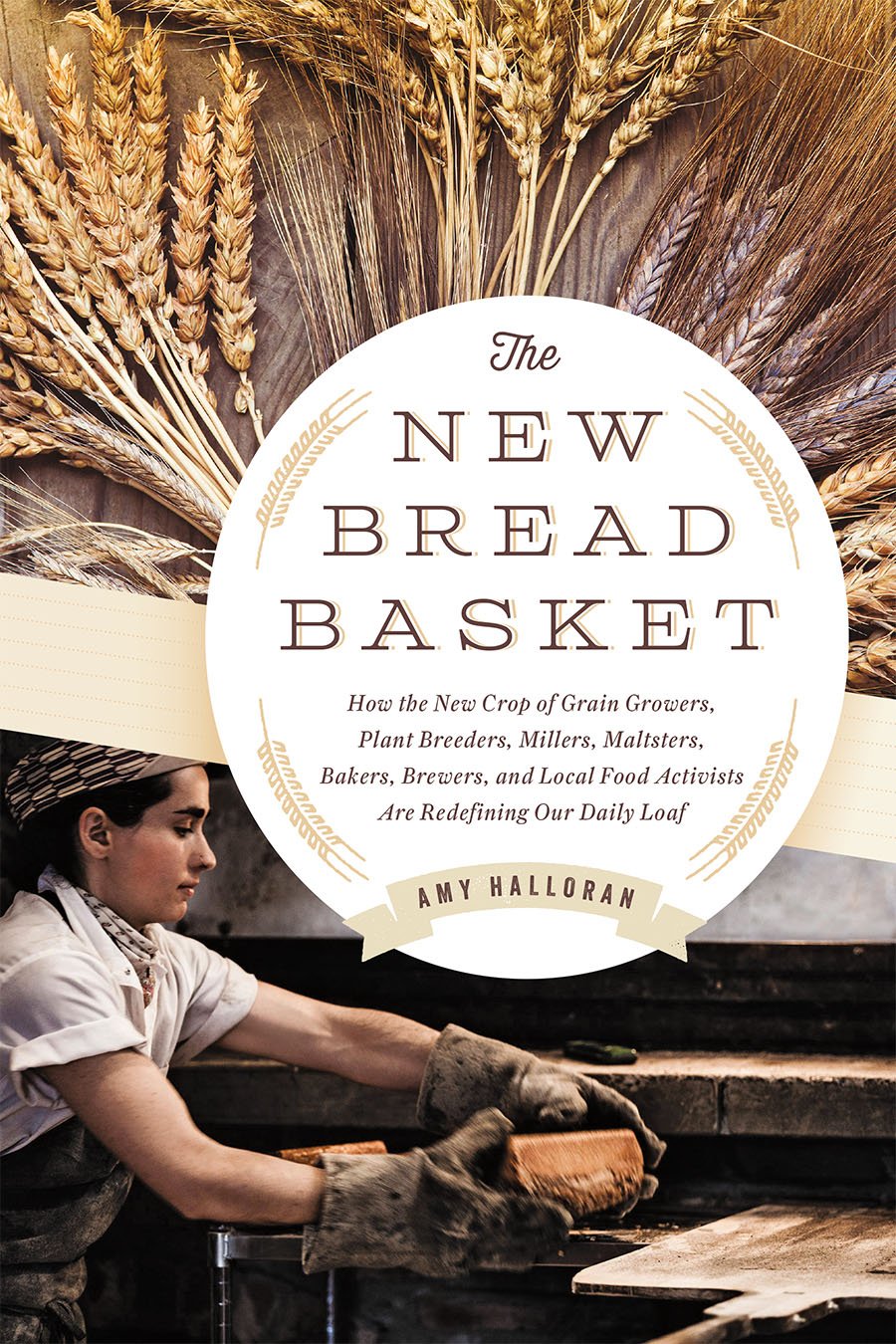

The New Bread Basket

How the New Crop of Grain Growers, Plant Breeders, Millers, Maltsters, Bakers, Brewers, and Local Food Activists Are Redefining Our Daily Loaf

| Pages: | 246 pages |

| Size: | 6 x 9 inch |

| Publisher: | Chelsea Green Publishing |

| Pub. Date: | July 27, 2015 |

| ISBN: | 9781603585675 |

The New Bread Basket

How the New Crop of Grain Growers, Plant Breeders, Millers, Maltsters, Bakers, Brewers, and Local Food Activists Are Redefining Our Daily Loaf

For more than 10,000 years, grains have been the staples of Western civilization. The stored energy of grain allowed our ancestors to shift from nomadic hunting and gathering and build settled communities—even great cities. Though most bread now comes from factory bakeries, the symbolism of wheat and bread—amber waves of grain, the staff of life—still carries great meaning.

Today, bread and beer are once again building community as a new band of farmers, bakers, millers, and maltsters work to reinvent local grain systems. The New Bread Basket tells their stories and reveals the village that stands behind every loaf and every pint.

While eating locally grown crops like heirloom tomatoes has become almost a cliché, grains are late in arriving to local tables, because growing them requires a lot of land and equipment. Milling, malting, and marketing take both tools and cooperation. The New Bread Basket reveals the bones of that cooperation, profiling the seed breeders, agronomists, and grassroots food activists who are collaborating with farmers, millers, bakers, and other local producers.

Take Andrea and Christian Stanley, a couple who taught themselves the craft of malting and opened the first malthouse in New England in one hundred years. Outside Ithaca, New York, bread from a farmer-miller-baker partnership has become an emblem in the battle against shale gas fracking. And in the Pacific Northwest, people are shifting grain markets from commodity exports to regional feed, food, and alcohol production. Such pioneering grain projects give consumers an alternative to industrial bread and beer, and return their production to a scale that respects people, local communities, and the health of the environment.

Many Americans today avoid gluten and carbohydrates. Yet, our shared history with grains—from the village baker to Wonder Bread—suggests that modern changes in farming and processing could be the real reason that grains have become suspect in popular nutrition. The people profiled in The New Bread Basket are returning to traditional methods like long sourdough fermentations that might address the dietary ills attributed to wheat. Their work and lives make our foundational crops visible, and vital, again.

Reviews and Praise

“Amy Halloran has created a baby book of the local grain movement and included snapshots of its older siblings: farming, milling, baking, brewing and oven building. What an amazing family, capable of hard work, persistence, and a generous exchange of information that has helped bring these ancient arts back onto our contemporary food scene. Amy explains how these symbiotic relationships have transformed the flavor, nutrition, resilience, and economies of the local grain movement."-- Richard Miscovich, baking instructor and author, From the Wood-Fired Oven

More Reviews and Praise

"The New Bread Basket is a love story about grain and the people captivated within its embrace. It is about community, connections, and conversations. From the history to the science to the passionate individuals and organizations involved, Amy's book will open your eyes to the revelations taking place every day in the name of grains. Expressive and eloquent, her writing reveals a personal journey that both informs and inspires. As a baker, I give Amy's book my highest recommendation. Reading it is truly a pleasure!"--Ciril Hitz, master bread baker and author, Baking Artisan Bread

“Halloran profiles a group of thoughtful, committed citizens who are helping to change the world…of grains. Beautifully capturing the descriptions of their mannerisms and ways, this book gives us reason to be hopeful that everyday people will heal the planet and our food system.”-- Amber Lambke, executive director, Maine Grain Alliance

"Amy Halloran is right on target. In The New Bread Basket, she not only brings all of us up to date on the most exciting new development in the world of grain -- local and regionally specific farming, milling, and baking -- but also introduces us to a whole new generation of budding, dedicated superstars who are making it happen. This is living tradition at its finest, reinvented in an exciting, contemporary manner. An idea whose time has come -- again."--Peter Reinhart, author, Bread Revolution

“In The New Bread Basket, Amy Halloran immerses herself in the burgeoning local grain movement, finding the farmers, wheat breeders, millers, bakers and brewers who are creating a new food culture. No one has explored this landscape with the depth and passion she brings to the subject. If you're curious about the future of bread, beer, or even the locavore movement itself, this is the place to start.”--Samuel Fromartz, author, In Search of the Perfect Loaf

Reviews and Praise

“Amy Halloran has created a baby book of the local grain movement and included snapshots of its older siblings: farming, milling, baking, brewing and oven building. What an amazing family, capable of hard work, persistence, and a generous exchange of information that has helped bring these ancient arts back onto our contemporary food scene. Amy explains how these symbiotic relationships have transformed the flavor, nutrition, resilience, and economies of the local grain movement."-- Richard Miscovich, baking instructor and author, From the Wood-Fired Oven

"The New Bread Basket is a love story about grain and the people captivated within its embrace. It is about community, connections, and conversations. From the history to the science to the passionate individuals and organizations involved, Amy's book will open your eyes to the revelations taking place every day in the name of grains. Expressive and eloquent, her writing reveals a personal journey that both informs and inspires. As a baker, I give Amy's book my highest recommendation. Reading it is truly a pleasure!"--Ciril Hitz, master bread baker and author, Baking Artisan Bread

“Halloran profiles a group of thoughtful, committed citizens who are helping to change the world…of grains. Beautifully capturing the descriptions of their mannerisms and ways, this book gives us reason to be hopeful that everyday people will heal the planet and our food system.”-- Amber Lambke, executive director, Maine Grain Alliance

"Amy Halloran is right on target. In The New Bread Basket, she not only brings all of us up to date on the most exciting new development in the world of grain -- local and regionally specific farming, milling, and baking -- but also introduces us to a whole new generation of budding, dedicated superstars who are making it happen. This is living tradition at its finest, reinvented in an exciting, contemporary manner. An idea whose time has come -- again."--Peter Reinhart, author, Bread Revolution

“In The New Bread Basket, Amy Halloran immerses herself in the burgeoning local grain movement, finding the farmers, wheat breeders, millers, bakers and brewers who are creating a new food culture. No one has explored this landscape with the depth and passion she brings to the subject. If you're curious about the future of bread, beer, or even the locavore movement itself, this is the place to start.”--Samuel Fromartz, author, In Search of the Perfect Loaf