Grow Vegetables Like You Mean It

In the United States, 40 percent of the food we produce is wasted. Ben Hartman is trying to put a dent in that dismal statistic. Inspired by Toyota’s “lean” approach to manufacturing, a production strategy designed to minimize waste and maximize efficiency while increasing profits.

In his practical how-to manual, Hartman shows how he has implemented lean thinking in every area of his work. Using the lean system, Hartman is able to earn a comfortable living on just an acre of land while finding life balance at the same time.

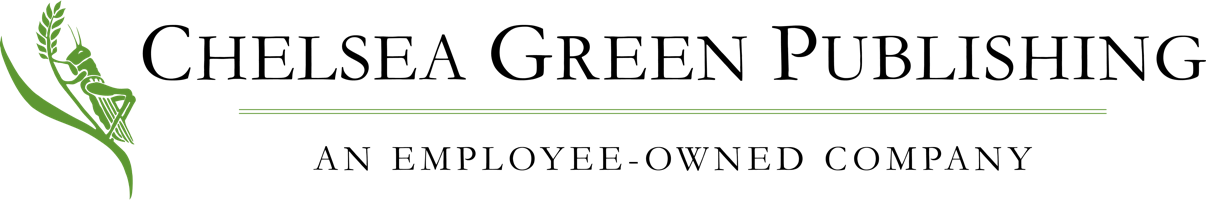

The excerpt below is from, The Lean Farm Guide to Growing Vegetables and has been adapted for the web.

In 2011 I received an email from Steve Brenneman, a CSA customer and the owner of an aluminum trailer factory. He had recently transformed his factory using the lean system, a Japanese invention designed to cut out waste and increase profits with less work. Brenneman offered to help us do the same on our farm. After initial skepticism (factory methods on farms haven’t always churned out sustainable outcomes), we took him up on his offer. Over the following several seasons, we proceeded to declutter our workspaces and cut waste from our processes. We now earn a comfortable living from our farm, and neither of us works off the property. We have stable, long-term customers, and our work doesn’t overburden us.

Five core lean principles have benefited us the most. These principles underlie the production systems in this book, and we use them to this day.

- Keep only the tools that add value.

- Let the customer define value.

- Identify the steps that add value.

- Cut out the muda—anything that does not add value.

- Practice kaizen—continuous improvement.

1. KEEP ONLY THE TOOLS THAT ADD VALUE

Lean relies on organization to keep workspaces clean. The most important step is sorting, discarding any item from your workspace that is not used every season to create value. This has not always been easy for us to do. At first we placed too much stock in tools that, realistically, we would never use. Now we have routines for constantly making sure we are surrounded only by what we need.

Farmers love to collect tools and hoard things. But we must check that instinct because everything we keep has a cost. It costs time to trip over shovels and look for hoes. It costs to store items—property taxes on buildings and expenses to maintain those buildings. Plus there is the mental cost of living with clutter. These are costs that suck energy and money without giving anything back besides the vacuous satisfaction of ownership.

2. LET THE CUSTOMER DEFINE VALUE

A second practice underlying our daily work is to always have our customers and their wishes in mind. We are growing food for them, and the products they want, both goods and services, guide our work. Specifically, we seek out answers to these three questions:

- What do our customers want?

- When do they want it?

- What amount do they want?

The more precisely we answer these questions and deliver on the answers, the more profitable we will be at year’s end. To be sure, we don’t fulfill every wish. For example, while customers might love watermelons, we don’t grow them because, for us, they are not profitable. Still, continually posing and answering the three questions ensures that paying customers, not our own whims, steer our farming.

3. IDENTIFY THE STEPS THAT ADD VALUE

The next principle we follow is to carefully trace value. In which steps do tomatoes and peppers and carrots become more valuable? When are we adding to their value, and when are we just spinning wheels? In a factory setting, value might be added when steel is welded to steel. That is the point when each piece is suddenly worth more. On the farm we’ve found that surprisingly few actions—seeding, harvesting, and washing food, for example—build value. These direct actions cause our food to be worth more.

4.CUT OUT THE MUDA—ANYTHING THAT DOES NOT ADD VALUE

According to the lean system, actions on your farm that don’t directly add value—like lawn mowing, cleaning, and leafing through catalogs—are considered muda. The closest English equivalent is “waste.” The Japanese managers who developed the lean system were precise when outlining forms of muda. Here they are as applied to the farm:

- Overproduction—spending resources on products that do not sell

- Waiting—products or people sitting idle

- Unnecessary transportation—too much driving, too little farming

- Overprocessing—washing and packaging more than the customer requires

- Too much inventory—unused supplies or sellable food plugging up the farm

- Unnecessary motion—any physical action that is not creating value

- Making defective products—twisted carrots, wormy tomatoes

- Overburdening (muri)—unreasonable effort to get a job done

- Uneven production and sales (mura)—peaks and valleys rather than a smooth, predictable workflow

- Unused talent—a good idea that went unspoken

On our farm we take muda elimination seriously. We look for the 10 mudas all the time. When we see them, as much as possible, we get rid of them. While muda is usually translated as “waste,” not all mudas are completely superflu-ous. We still file taxes, occasionally pull weeds, and send invoices to customers, even if these actions do not directly cause our products to be worth more. Not all mudas should be completely eliminated. The goal, rather, is to mini-mize the amount of time and energy given to non-value-adding activities.

We’ve come to realize that every activity we perform is either muda or value adding. There are no exceptions. Our job is to see the difference, and steer toward value. If we find ourselves performing a muda task, we ask, how can we shorten it or, better yet, eliminate it? As Shigeo Shingo, a Japanese engineer and arguably the world’s leading expert on manufacturing efficiency, observed, only the last turn of a bolt tightens it—the rest is just movement. We want to focus on bolt tightening, so to speak—on seeding, washing, harvesting, and selling—and minimize everything else. Cutting out muda has been a powerful force on our farm, increasing our profits every year, while we work less.

5. PRACTICE KAIZEN—CONTINUOUS IMPROVEMENT

The final step is to practice kaizen, or continuous improvement, rooting out more waste every year from the farm, and aligning production more tightly with customer demand. We have adopted the philosophy “When you fix it, fix it again.” Our goal is to create a farm culture where everyone on the team joins together in an effort to achieve zero-waste production.

Recommended Reads

Recent Articles

Asparagus is a delicious vegetable with a layered history. How did this aspiring spear make its way from growing in the wild to appearing on our plates? The following is an excerpt from the The Seed Detective by Adam Alexander. It has been adapted for the web. “Nature gives us the key to every secret…

Read MoreInterested in growing trees? Here are some tips on successfully planting, transplanting, and pruning trees to create a flourishing forest garden! The following is an excerpt from The Home-Scale Forest Garden by Dani Baker. It has been adapted for the web. Planting Potted Trees and Shrubs If you order potted trees, check with your supplier to…

Read MoreWith the right strategies and practices, composting on a small farm is surprisingly easy and inexpensive. Just follow these steps for making compost, and your farm will be thriving in no time! The following excerpt is from The Lean Farm Guide to Growing Vegetables by Ben Hartman. It has been adapted for the web. (All photographs by Ben…

Read MoreGarlic mustard: while known as “invasive,” this plant can be consumed in its entirety and has great nutritional value. Plus, the garlic-flavor is a perfect addition to any recipe that calls for mustard! The following are excerpts from Beyond the War on Invasive Species by Tao Orion and The Wild Wisdom of Weeds by Katrina…

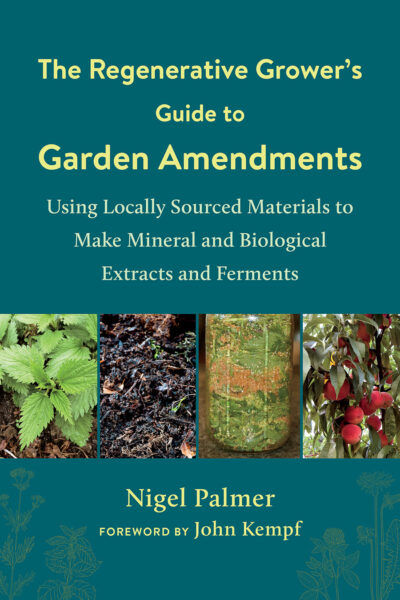

Read MoreEveryone loves a refreshing, fermented, nutritious drink…even your garden! Take your fermentation skills out of the kitchen and into the garden by brewing fermented plant juice. The following is an excerpt from The Regenerative Grower’s Guide to Garden Amendments by Nigel Palmer. It has been adapted for the web. How to Make Fermented Plant Juice Fermented…

Read More