EXCERPTS

| Pages: | 304 pages |

| Book Art: | Full-color photographs and illustrations throughout |

| Size: | 7 x 10 inch |

| Publisher: | Chelsea Green Publishing |

| Pub. Date: | July 20, 2021 |

| ISBN: | 9781645020264 |

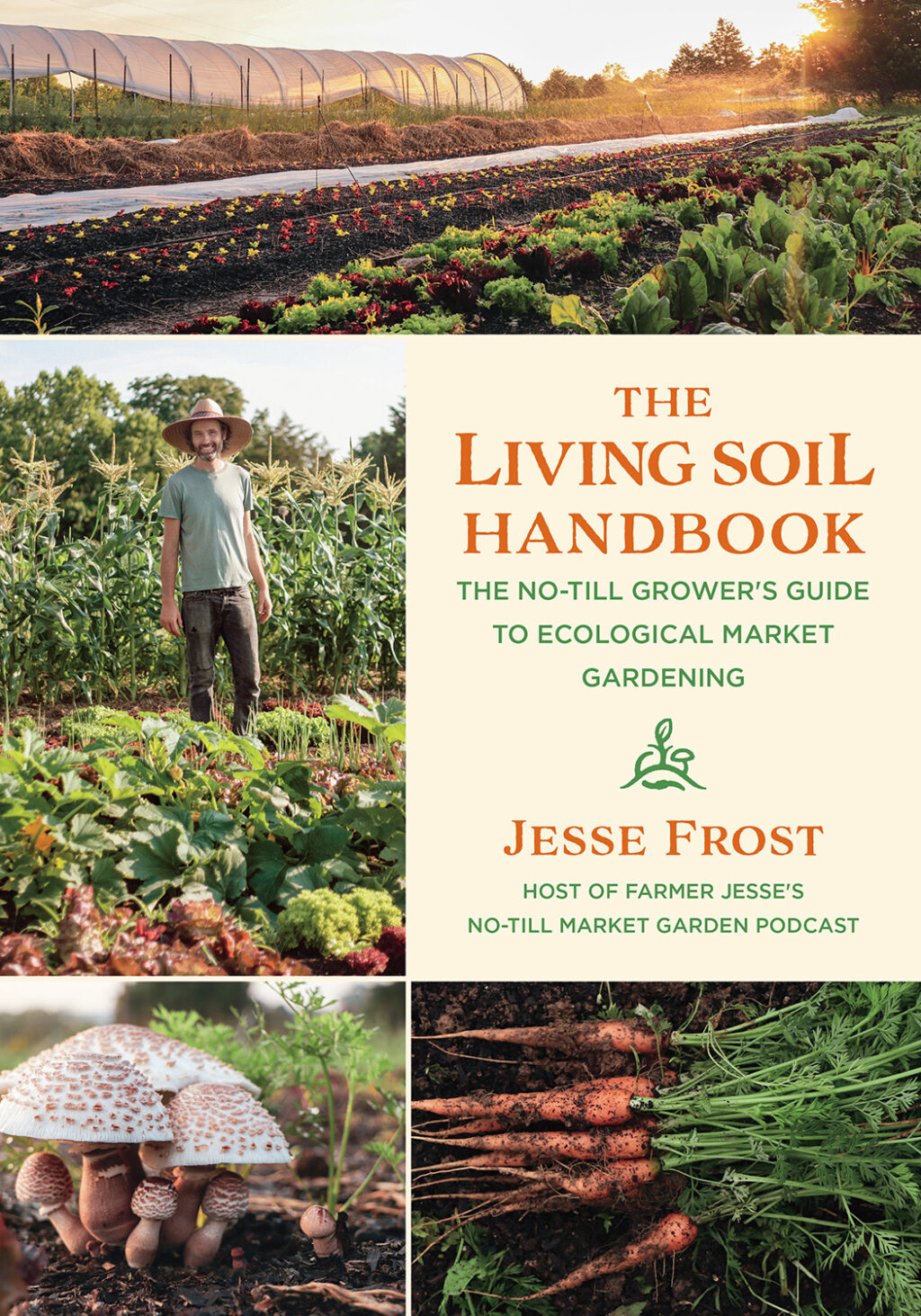

The Living Soil Handbook

The No-Till Grower’s Guide to Ecological Market Gardening

Principles and farm-tested practices for no-till market gardening–for healthier, more productive soil!

From the host of the popular The No-Till Market Garden Podcast—heard around the world with nearly one million downloads!

Discovering how to meet the soil’s needs is the key task for every market gardener. In this comprehensive guide, Farmer Jesse Frost shares all he has learned through experience and experimentation with no-till practices on his home farm in Kentucky and from interviews and visits with highly successful market gardeners in his role as host of The No-Till Market Garden Podcast.

The Living Soil Handbook is centered around the three basic principles of no-till market gardening:

- Disturb the soil as little as possible

- Keep it covered as much as possible

- Keep it planted as much as possible.

Farmer Jesse then guides readers in applying those principles to their own garden environment, with their own materials, to meet their own goals.

Beginning with an exploration of the importance of photosynthesis to living soil, Jesse provides in-depth information on:

- Turning over beds

- Using compost and mulch

- Path management

- Incorporating biology, maintaining fertility

- Cover cropping

- Diversifying plantings through intercropping

- Production methods for seven major crops

Throughout, the book emphasizes practical information on all the best tools and practices for growers who want to build their livelihood around maximizing the health of their soil.

Farmer Jesse reminds growers that “as possible” is the mantra for protecting the living soil: disturb the soil as little as you possibly can in your context. He does not believe that growers should anguish over what does and does not qualify as “no-till.” If you are using a tool to promote soil life and biology, that’s the goal. Jesse’s goal with The Living Soil Handbook is to provide a comprehensive set of options, materials, and field-tested practices to inspire growers to design a soil-nurturing no-till system in their unique garden or farm ecosystem.

“[A] practical, informative debut. . . .Gardeners interested in sustainable agriculture will find this a great place to start.”—Publishers Weekly

“Frost offers a comprehensive, science-based, sympathetic, wholly practical guide to soil building, that most critical factor in vegetable gardening for market growers and home gardeners alike. A gift to any vegetable plot that will keep on giving.”—Booklist (starred review)

Reviews and Praise

“Over my years practicing no-till market gardening, I’ve come to truly appreciate listening to The No-Till Market Garden Podcast and Farmer Jesse’s exploration of no-till systems. Now, this research is inked into Jesse’s very well-written and valuable guide, The Living Soil Handbook. This book is a gold mine filled with tips, tricks, and effective practices you can apply to your crop itineraries. I advise any grower to follow Jesse’s mantra: A no-till system is not a dogma, it’s a direction.”—Jean-Martin Fortier, author of The Market Gardener

More Reviews and Praise

“The best way to produce healthier soils, fight climate change, and reduce work all at the same time is to disturb the soil less. The Living Soil Handbook shows growers how to do just that. I highly recommend this practical and beautifully designed book.”—Ben Hartman, author of The Lean Farm and The Lean Farm Guide to Growing Vegetables

“In this wonderful new book, Jesse Frost offers a clear and friendly explanation of why and how you can grow successfully when your methods are fully in tune with nature’s processes. Beautifully illustrated by Jesse’s wife, Hannah Crabtree, The Living Soil Handbook provides a full range of experience-based advice to aspiring growers and gardeners on major topics such as soil fertility and mulches as well as small but important details like bed and path width. Jesse values practicality over dogma, and keeps it achievable: ‘Disturb the soil as little as possible.’”—Charles Dowding, creator of Charles Dowding’s No-Dig Gardening Course

“The Living Soil Handbook is a must-read for growers who want to achieve the long-held organic objective of feeding crops by feeding the soil. It goes beyond the mechanics of no-till to explain why it’s important to keep the soil ‘as undisturbed, as well covered, and as fully planted as possible.’ With the understanding of why to do these things, growers can customize their soil care systems for any region. Whether or not your goal is to go completely no-till, Jesse Frost’s book is a great companion to help you figure out how to ‘disturb the soil as little as you possibly can in your context.’ With an emphasis on understanding soil ecosystems, this book allows growers to improvise their own solutions rooted in soil health.”—Andrew Mefferd, editor, Growing for Market magazine; author of The Greenhouse and Hoophouse Grower’s Handbook and The Organic No-Till Farming Revolution

“Jesse Frost’s The Living Soil Handbook is a terrific, practical application of the no-till principles for which he and his No-Till Market Garden Podcast have become known and respected. Disturbing the soil as little as possible—even when managing garden paths, for example—is one theme of this book about letting the living soil live and how to do so. Beautifully illustrated, this is a great read full of useful advice that will perfect your growing game.”—Jeff Lowenfels, author of Teaming with Fungi

“The Living Soil Handbook is a must-have resource for those who wish to reduce or eliminate tillage, build soil biology, intensify production, and create a more ecological, regenerative, and successful farm. Farmer Jesse integrates the experiences of a multitude of farmers and his years of research with pertinent soil science in this easy-to-read guide to help grow more resilient farms in the face of climate chaos. It all goes back to the soil and building life!”—Elizabeth and Paul Kaiser, founders and farmers, Singing Frogs Farm

“As a lifelong farmer who is skeptical of absolute practices and catchphrases like ‘no-till,’ I’m happy to say that Jesse Frost has done an excellent job of compiling resources and information to explain the tenets of healthy living soil. With a skillful, personable writing style, Jesse offers effective farming techniques and provides a compelling case to disturb the soil as little as possible as well as to keep it planted and covered as much as possible. The Living Soil Handbook is a great read for beginning and seasoned farmers alike.”—Clara Coleman, owner and operator, Four Season Farm; creator of #RealFarmerCare

“Jesse Frost has made an invaluable addition to the nascent library of no-till market garden manuals. If you want to grow vegetables without tillage, read this book closely and reference it often. Like crops growing from a vibrant soil food web, Jesse’s insights pull from interactions with innovative no-till growers across the United States and beyond—and bear fruit worth savoring. Jesse has synthesized this incredible diversity into a comprehensive manual that takes no-till to a deeper level. I learned something new on almost every page. A magnificent union of information gathering and first-person know-how, The Living Soil Handbook is a must-read for every soil caretaker.”—Daniel Mays, author of The No-Till Organic Vegetable Farm

“While no-till growing has been popular for amateur gardeners for some time, it is only more recently that commercial growers have embraced its potential. The Living Soil Handbook is beautifully clear, making both the complexity of soil biology and the technical crop detail engaging and accessible. Jesse Frost demonstrates the benefits of using no till methods and he also takes us through, in some detail, the range of methods possible at different scales. He is no starry-eyed evangelist though. He explores his failures as well as what has worked well, and points out areas where more research and trials are needed, for instance in successful crop termination. Though this book is aimed at the ecological market gardener, anyone with an interest in growing vegetables with the minimal impact on their soil will thoroughly enjoy and learn from Jesse’s sound advice.”—Ben Raskin, head of horticulture and agroforestry, Soil Association; author of The Woodchip Handbook

“The Living Soil Handbook speaks to Jesse Frost’s experimental and inquisitive nature whilst seeking out practical and reliable solutions. Garnering wisdom from growers in many regions, as well as from his own experience, Jesse delves deep into what I consider an optimal approach to annual vegetable production. This book explores the pioneering no-dig market gardening system with deep woodchip pathways that I have established at Ridgedale, along with many other complementary approaches for achieving the same outcomes: thriving soil biology, practical workflows, and abundant harvests. It proves once again that it is our pattern-thinking that is important, and that we have a multitude of solutions at our disposal. We are microbe farmers, after all, and this book is a great addition to the literature to help you achieve beautiful and bountiful results.”—Richard Perkins, author of Regenerative Agriculture and Ridgedale Farm Builds

Publishers Weekly—

"[A] practical, informative debut. . . .Gardeners interested in sustainable agriculture will find this a great place to start."

Booklist Starred Review—

"Author Frost offers a comprehensive, science-based, sympathetic, wholly practical guide to soil building, that most critical factor in vegetable gardening for market growers and home gardeners alike. A gift to any vegetable plot that will keep on giving."

Reviews and Praise

“Over my years practicing no-till market gardening, I’ve come to truly appreciate listening to The No-Till Market Garden Podcast and Farmer Jesse’s exploration of no-till systems. Now, this research is inked into Jesse’s very well-written and valuable guide, The Living Soil Handbook. This book is a gold mine filled with tips, tricks, and effective practices you can apply to your crop itineraries. I advise any grower to follow Jesse’s mantra: A no-till system is not a dogma, it’s a direction.”—Jean-Martin Fortier, author of The Market Gardener

“The best way to produce healthier soils, fight climate change, and reduce work all at the same time is to disturb the soil less. The Living Soil Handbook shows growers how to do just that. I highly recommend this practical and beautifully designed book.”—Ben Hartman, author of The Lean Farm and The Lean Farm Guide to Growing Vegetables

“In this wonderful new book, Jesse Frost offers a clear and friendly explanation of why and how you can grow successfully when your methods are fully in tune with nature’s processes. Beautifully illustrated by Jesse’s wife, Hannah Crabtree, The Living Soil Handbook provides a full range of experience-based advice to aspiring growers and gardeners on major topics such as soil fertility and mulches as well as small but important details like bed and path width. Jesse values practicality over dogma, and keeps it achievable: ‘Disturb the soil as little as possible.’”—Charles Dowding, creator of Charles Dowding’s No-Dig Gardening Course

“The Living Soil Handbook is a must-read for growers who want to achieve the long-held organic objective of feeding crops by feeding the soil. It goes beyond the mechanics of no-till to explain why it’s important to keep the soil ‘as undisturbed, as well covered, and as fully planted as possible.’ With the understanding of why to do these things, growers can customize their soil care systems for any region. Whether or not your goal is to go completely no-till, Jesse Frost’s book is a great companion to help you figure out how to ‘disturb the soil as little as you possibly can in your context.’ With an emphasis on understanding soil ecosystems, this book allows growers to improvise their own solutions rooted in soil health.”—Andrew Mefferd, editor, Growing for Market magazine; author of The Greenhouse and Hoophouse Grower’s Handbook and The Organic No-Till Farming Revolution

“Jesse Frost’s The Living Soil Handbook is a terrific, practical application of the no-till principles for which he and his No-Till Market Garden Podcast have become known and respected. Disturbing the soil as little as possible—even when managing garden paths, for example—is one theme of this book about letting the living soil live and how to do so. Beautifully illustrated, this is a great read full of useful advice that will perfect your growing game.”—Jeff Lowenfels, author of Teaming with Fungi

“The Living Soil Handbook is a must-have resource for those who wish to reduce or eliminate tillage, build soil biology, intensify production, and create a more ecological, regenerative, and successful farm. Farmer Jesse integrates the experiences of a multitude of farmers and his years of research with pertinent soil science in this easy-to-read guide to help grow more resilient farms in the face of climate chaos. It all goes back to the soil and building life!”—Elizabeth and Paul Kaiser, founders and farmers, Singing Frogs Farm

“As a lifelong farmer who is skeptical of absolute practices and catchphrases like ‘no-till,’ I’m happy to say that Jesse Frost has done an excellent job of compiling resources and information to explain the tenets of healthy living soil. With a skillful, personable writing style, Jesse offers effective farming techniques and provides a compelling case to disturb the soil as little as possible as well as to keep it planted and covered as much as possible. The Living Soil Handbook is a great read for beginning and seasoned farmers alike.”—Clara Coleman, owner and operator, Four Season Farm; creator of #RealFarmerCare

“Jesse Frost has made an invaluable addition to the nascent library of no-till market garden manuals. If you want to grow vegetables without tillage, read this book closely and reference it often. Like crops growing from a vibrant soil food web, Jesse’s insights pull from interactions with innovative no-till growers across the United States and beyond—and bear fruit worth savoring. Jesse has synthesized this incredible diversity into a comprehensive manual that takes no-till to a deeper level. I learned something new on almost every page. A magnificent union of information gathering and first-person know-how, The Living Soil Handbook is a must-read for every soil caretaker.”—Daniel Mays, author of The No-Till Organic Vegetable Farm

“While no-till growing has been popular for amateur gardeners for some time, it is only more recently that commercial growers have embraced its potential. The Living Soil Handbook is beautifully clear, making both the complexity of soil biology and the technical crop detail engaging and accessible. Jesse Frost demonstrates the benefits of using no till methods and he also takes us through, in some detail, the range of methods possible at different scales. He is no starry-eyed evangelist though. He explores his failures as well as what has worked well, and points out areas where more research and trials are needed, for instance in successful crop termination. Though this book is aimed at the ecological market gardener, anyone with an interest in growing vegetables with the minimal impact on their soil will thoroughly enjoy and learn from Jesse’s sound advice.”—Ben Raskin, head of horticulture and agroforestry, Soil Association; author of The Woodchip Handbook

“The Living Soil Handbook speaks to Jesse Frost’s experimental and inquisitive nature whilst seeking out practical and reliable solutions. Garnering wisdom from growers in many regions, as well as from his own experience, Jesse delves deep into what I consider an optimal approach to annual vegetable production. This book explores the pioneering no-dig market gardening system with deep woodchip pathways that I have established at Ridgedale, along with many other complementary approaches for achieving the same outcomes: thriving soil biology, practical workflows, and abundant harvests. It proves once again that it is our pattern-thinking that is important, and that we have a multitude of solutions at our disposal. We are microbe farmers, after all, and this book is a great addition to the literature to help you achieve beautiful and bountiful results.”—Richard Perkins, author of Regenerative Agriculture and Ridgedale Farm Builds

Publishers Weekly—

"[A] practical, informative debut. . . .Gardeners interested in sustainable agriculture will find this a great place to start."

Booklist Starred Review—

"Author Frost offers a comprehensive, science-based, sympathetic, wholly practical guide to soil building, that most critical factor in vegetable gardening for market growers and home gardeners alike. A gift to any vegetable plot that will keep on giving."