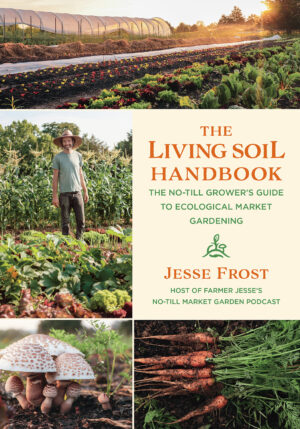

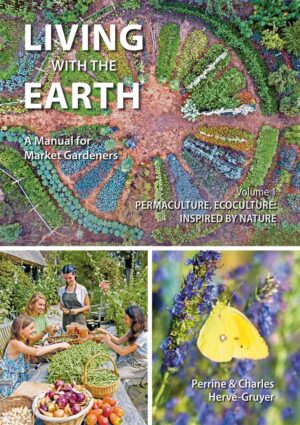

Living with the Earth, Volume 1

Permaculture, Ecoculture: Inspired by Nature

Living with the Earth, Volume 1

Permaculture, Ecoculture: Inspired by Nature

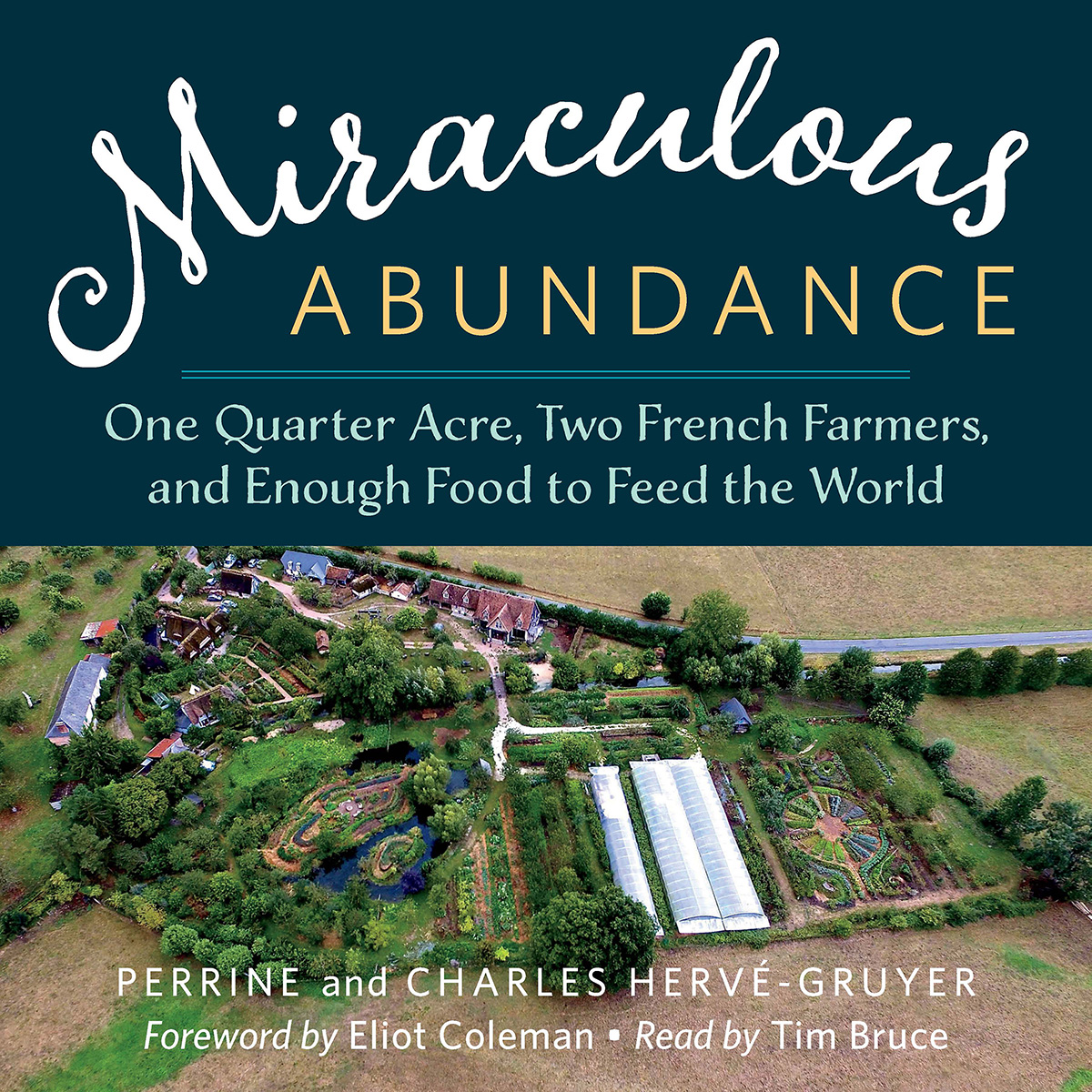

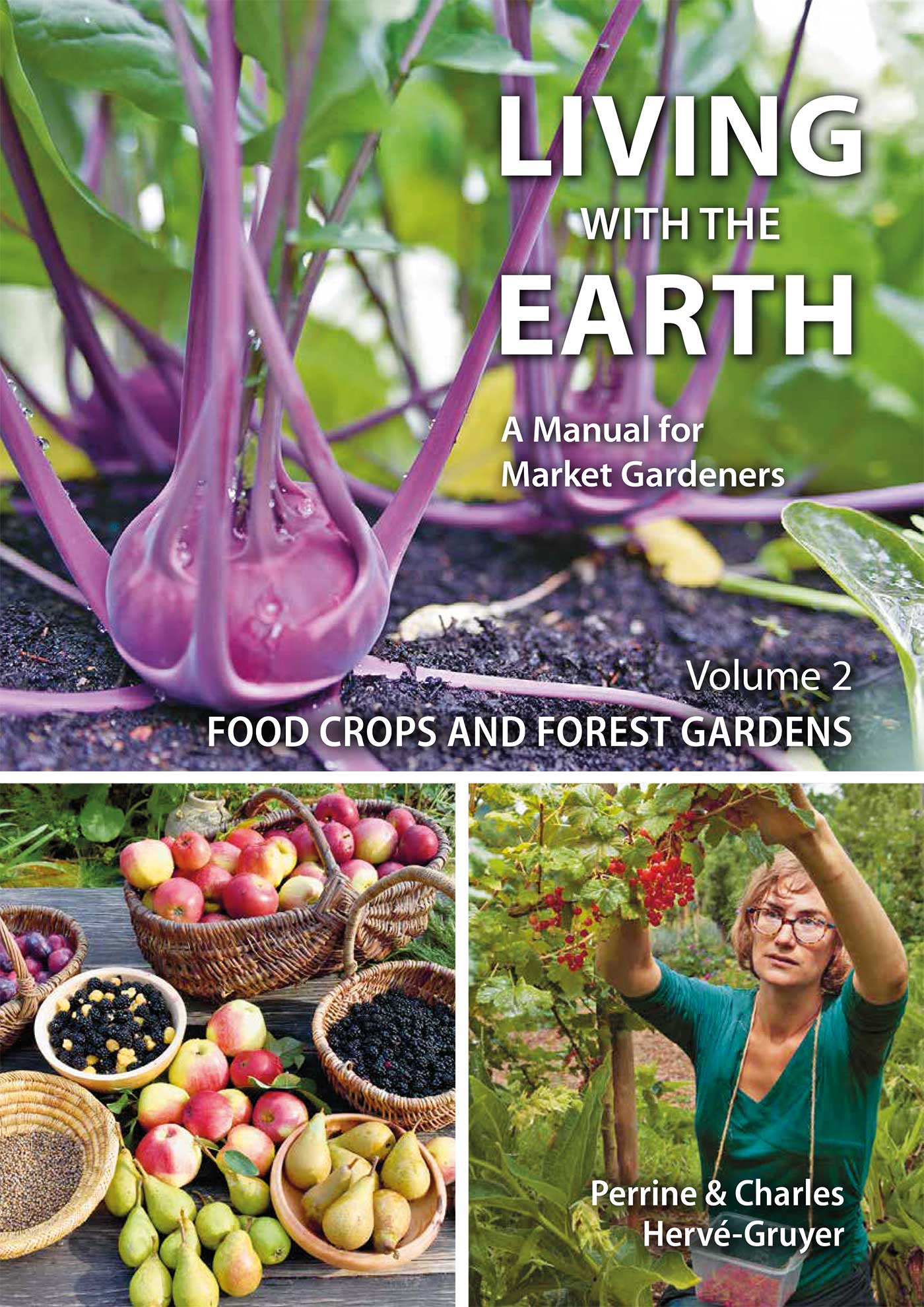

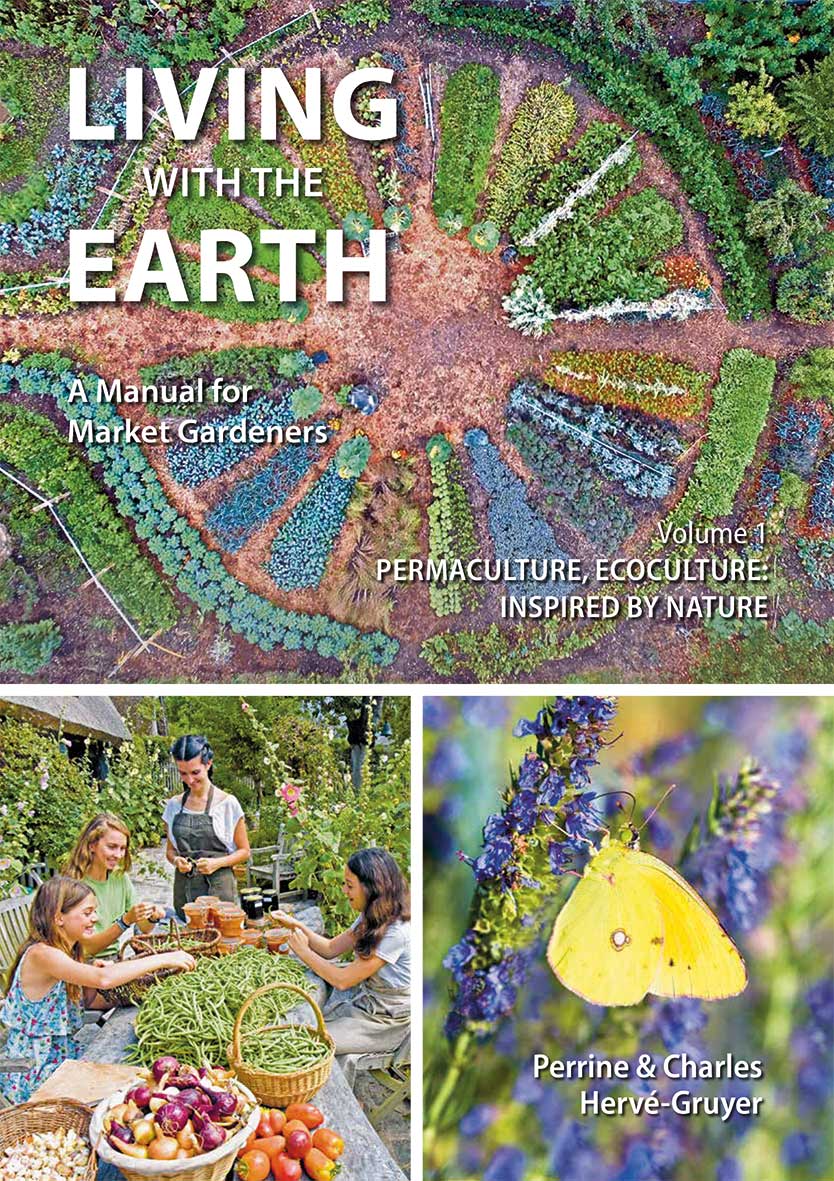

In 2006, Perrine and Charles Hervé-Gruyer set out on a mission to discover a new form of agriculture that provides organic crops and creates meaningful employment in the local community. Using a combination of biointensive methods and permaculture design, which they have named ‘ecoculture’, and backed by scientific research, resulted in their farm producing abundantly, sequestering carbon and freeing up land for nature.

This beautifully illustrated, comprehensive volume will show you how natural systems work, and discover many simple and effective techniques that create an ecological diverse garden or a highly productive farm. The in-depth section on ‘Nature’s School’ explains weather patterns, soil types, and ecosystem services to give the reader sound knowledge of the environment they are growing in. The section on ‘Designing a Farm’ provides everything needed to implement an abundant food system, from understanding permaculture and its design tools, the full design process and the designs used on the Bec Hellouin farm as a successful example. Additional chapters on composting, mulching, fertilisers, green manures and working with beneficial microorganisms offers the reader a selection of tools for creating healthy soil in a closed loop system.

Full of first-hand tried and tested experience from Bec Hellouin, there is also a synthesis of the authors’ research and the scientific and technical monitoring carried out on the farm. This is a unique, groundbreaking book for the serious gardener, farmer, agronomist and permaculture designer.

Reviews and Praise

"Goodness, this book sings! Living with the Earth braids ecological farming, scientific rigor, and ancient wisdom with all the practicalities of a manual that actually helps you do the work. The immense beauty this book represents with its lyrical writing, photos, and illustrations pulls you into the world of miracles. Our world-tended with loving hands in a simple, effective, and regenerative way. This is ecological farming at its best."—Erik Ohlsen, author of The Regenerative Landscaper

More Reviews and Praise

"Full of deep hope, Living with the Earth is a user’s manual for our time, for all those (and that means: more and more of us) who will be at least in part living off the land. Gardening is a political act, and engaging thoughtfully and determinedly in this politics is an essential form of care for future generations... Our growing gardens will be oases of life and sanity in difficult times."—Prof. Rupert Read, tinyholder; Co-Director, Climate Majority Project; author of Parents for a Future

"If you grow food or want to start, please read this book! Just like the Bec Hellouin farm itself, Living with the Earth, is packed full of useful information and advice, and occupies many different niches."—Andy Goldring, CEO, Permaculture Association

"Charming, practical, much needed, comprehensive, useful, and profound, are all words that come to mind as I read this work."—John D. Liu, Filmmaker; Ecologist; Ecosystem Ambassador, Commonland Foundation

"Written by the owners of the renowned Ferme du Bec Hellouin in France. Guiding the reader to a new perspective on food production and reconnecting with nature. Each section gives the reader real-life context. It will inspire the newbie as well as the expert designers and makes an incredibly useful tool for any permaculture designer. The in depth data, drawings and tables are of huge value, backing up these important techniques with scientific observations."—Lorenzo Costa, Permaculture magazine, PM118 Winter 2023

Reviews and Praise

"Goodness, this book sings! Living with the Earth braids ecological farming, scientific rigor, and ancient wisdom with all the practicalities of a manual that actually helps you do the work. The immense beauty this book represents with its lyrical writing, photos, and illustrations pulls you into the world of miracles. Our world-tended with loving hands in a simple, effective, and regenerative way. This is ecological farming at its best."—Erik Ohlsen, author of The Regenerative Landscaper

"Full of deep hope, Living with the Earth is a user’s manual for our time, for all those (and that means: more and more of us) who will be at least in part living off the land. Gardening is a political act, and engaging thoughtfully and determinedly in this politics is an essential form of care for future generations... Our growing gardens will be oases of life and sanity in difficult times."—Prof. Rupert Read, tinyholder; Co-Director, Climate Majority Project; author of Parents for a Future

"If you grow food or want to start, please read this book! Just like the Bec Hellouin farm itself, Living with the Earth, is packed full of useful information and advice, and occupies many different niches."—Andy Goldring, CEO, Permaculture Association

"Charming, practical, much needed, comprehensive, useful, and profound, are all words that come to mind as I read this work."—John D. Liu, Filmmaker; Ecologist; Ecosystem Ambassador, Commonland Foundation

"Written by the owners of the renowned Ferme du Bec Hellouin in France. Guiding the reader to a new perspective on food production and reconnecting with nature. Each section gives the reader real-life context. It will inspire the newbie as well as the expert designers and makes an incredibly useful tool for any permaculture designer. The in depth data, drawings and tables are of huge value, backing up these important techniques with scientific observations."—Lorenzo Costa, Permaculture magazine, PM118 Winter 2023